Thought I would do a somewhat different blog entry this time - specifically looking at something that is probably a new stalker topic, but may still catch some seasoned hands off guard.

The topic? How to mount a difficult trophy.

In the past, I've been lucky enough to bag some wonderful Roe with Peter at County Deer Stalking. However, one day a few months ago I tagged a great Fallow buck:

Figure : Fallow Buck, November 2012, County Deer Stalking

Delighted with my success, needless to say I was looking forward to the trophy, which Peter had kindly prepared. All good so far!

Now, to date I have had a nice stock of Roe sized shields and mounting plates. For the absolute beginner, these are bits of metal that wedge inside the hole in the skull (brain cavity) and are sufficiently sized and designed to sit very snugly in place. In turn, you then drill a hole in the wooden shield and run the bolt / screw through the back and tighten it until it is rock solid stead. It's then ready to mount.

This in itself is a task I undertook with shaking hands the first time I did it, as it all feels very unnatural (why am I drilling a hole in this bit of wood? Surely everything comes 'pre-done' in this day and age?!). There are some good videos on YouTube that can help with this.

But - with the Fallow, demanding a bigger shield - I just couldn't get a metal plate big enough to fill the cavity. The next size up was Red deer, of which are a lot bigger. Incidentally the shield I purchased is for a Medium Sika deer, and seems to fit just right. So how do you do it?

Figure : With a Roe mount inside for size - it's just too small!

Figure : With the Red deer mount inside - it's just too big!

The answer - Vehicle Filler.

To those of you who (like me) are not of an automotive mind, or not acquainted with repairing your own car, this may seem a bit strange. The stated purpose is such that, should you scrape your car and have a dent you need to fill before painting, you mix up some of this, trowel it in to the scrape, sand it down with sandpaper, then paint over it. Of course, we are not interested in the painting, but we are very much interested in filling a gap so that we can drill in to it.

So what we are in effect doing is filling the brain cavity so we can drill it.

I personally used 'ISOPON P38 Easy Sand' tagged as "Repairs Dents and Scratches", purchased from an online retailer but also available in all good car shops like Halfords I would expect, at a cost of about £10 - £15. I purchased a 250ml tin and this exactly filled my Fallow cavity with virtually nothing to spare, so you may wish to consider buying a 500ml tub if you have a couple of heads to do.

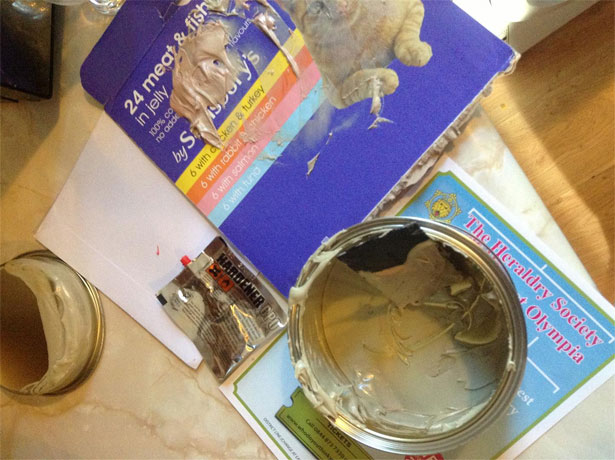

On opening the tin, you are met with instructions (very clear and useful - read them!), a little sachet of quick drying chemical (keep away from children, pets, eyes, skin, etc) and the main, well, glop itself. WARNING: It does have a fairly strong smell of chemical, so do open a window or ideally do it outside.

Figure : Messy but necessary - glop on the right, hardener on the left

I transferred the glop on to a bit of box cardboard using the tiny plastic trowel provided, but you may find it easier to use a decorating spatula or similar. After swirling this around a bit, apply some of the hardening chemical. Note - it will not go hard by itself, you NEED to apply the chemical. The ratio stated is "for a golf ball size of glop, use one pea size of chemical" (OK, maybe it doesn't say "glop", but you get the idea!). Squeeze the chemical in, with mine being bright red against the beige sludge of the glop, until there are no streaks of colour left.

Now, you have about 5 minutes to pour / apply in to the skull cavity before it starts to set. I trowelled mine in and kept making up more, applying more chemical as I became more confident. I used a bit of kitchen paper to clean off any spillages from around the outside of the cavity as I did so, but in fairness it was actually very easy to aim as it's so slow to pour.

After about an hour or so, while still feeling warm, it felt rock hard. This is ready to be sanded so it's a flat surface and then ready to drill.

So there we have it. How to fill a cavity, ready for drilling and hanging.

Figure : Drying, ready to sand off and drill